Asaclean is a high-performance purging compound widely used in the plastic injection molding and extrusion industries. It is specifically designed to clean thermoplastic processing equipment, such as injection molding machines, extruders, and blow molding machines, helping to reduce machine downtime, improve product quality, and minimize material waste.

Key Features:

- Effective Cleaning: Asaclean efficiently removes residual resin, colorants, and contaminants from machinery, preventing defects in the next production run.

- Versatility: Suitable for use with a wide range of resins, including polyolefins, polycarbonates, and more, making it adaptable to various production needs.

- Ease of Use: Simple to apply with minimal adjustments to the existing machinery, allowing for quick and effective purging between production runs.

- Cost-Effective: By reducing the amount of scrap material and the time spent on cleaning, Asaclean contributes to overall cost savings in the manufacturing process.

Applications:

- Injection Molding: Used to purge residual material from molding machines, ensuring color and material changes are clean and efficient.

- Extrusion: Helps maintain the integrity of extruded products by preventing contamination and ensuring smooth transitions between different materials or colors.

- Blow Molding: Ensures high-quality production by keeping blow molding equipment free from contaminants and build-up.

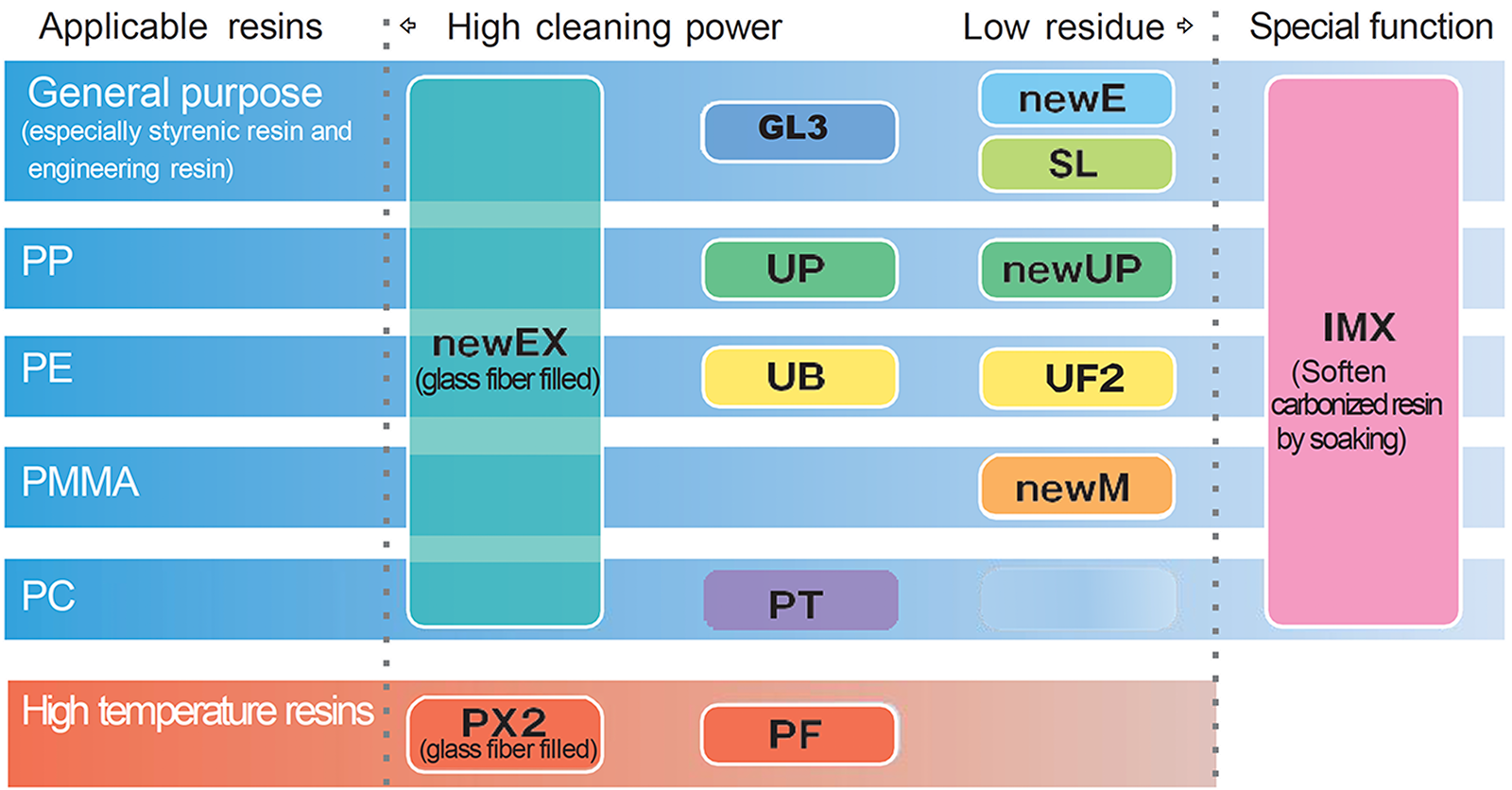

Asaclean™ Product Lineup

newEX Grade

Maximum Grade

newEX Grade has the strongest cleaning power against difficult-to-clean resins and contamination. newEX contains glass fibre.

U Grade

Versatile, balanced Grade

U Grade is versatile, with an unequalled balance between cleaning power and residue. The next strongest grade after newEX Grade, and you can use it for sealing and hot runners.

IMX Grade

High performance soaking grade

Softens and removes stubborn stains that you cannot remove even with newEX, and when used in combination with newEX or other Asaclean™ products, it provides even better cleaning results.

GL3 Grade

Universal Grade

GL3 Grade is a cost-effective purging compound for primary colour and material changeover.

newE Grade

Low residue Grade

Suitable for transparent resins and high-flow resins where you require low residue. You can switch and clean engineering plastics such as PA6 and POM at low temperatures. You can use it for selaing and hot runners.

SL Grade

Grade for rinsing and sealing

Suitable for transparent resins and high-flow resins where you require low residue. You can switch and clean engineering plastics such as PA6 and POM at low temperatures. You can use it for selaing and hot runners.

PX2 Grade

High-temperature grade without glass fibre

High cleaning power grade for high temperatures (280-420℃) such as PPS, PEEK, LCP, and PEI. PX2 Grade can suppress smoke generation.

PF Grade

High temperature grade without glass fiber

Excellent thermal stability in the high temperature (280-420℃) range and reduced smoke generation. You can use for sealing and hot runners at high temperatures.

UP Grade

Superior cleaning PP

Excellent colour change performance for PP. UP Grade can clean up initial black spots and stains during PP moulding. Suitable for PP blow and injection moulding.

newUP Grade

Low residue for PP

Suitable for PP moulding where low residues are preferred; compatibility with PP and low residues allows for quick changeover to PP natural.

UB Grade

Superior cleaning PE

An excellent colour change performance for PE. UB Grade can clean up initial black spots and stains during PE moulding. Suitable for PE blow and injection moulding.

UF2 Grade

Low residue for PE-blown film and sheet applications

Ideal for PE-blown film and sheet applications. UF2 Grade can remove initial burn and gel.

PT Grade

Designed for switching to PC, transparency is required

Effective for switching from other resins to PC, where transparency is required, and effective for changing resins at 280-360℃ with excellent low residue in PC.

newM Grade

Specialized for PMMA, transparency is required

Superior for the colour changeover in PMMA.